WE BRING INNOVATION

TO SUPPLY CHAIN

Intelligent Logistics Assets

PAFT Smart Plastic Pallets are designed as intelligent logistics assets. Each pallet carries a unique RFID identity that stores and transmits its full lifecycle data, transforming traditional pallets into smart, trackable units within the warehouse ecosystem.

RFID Technology Integration

The core components powering our smart warehouse ecosystem

RFID Tags

Embedded RFID tags provide unique identification and real-time tracking for every pallet.

Readers & Antennas

Installed on forklifts, racks, aisles, and gates to capture movement automatically.

Cloud iWMS Platform

All RFID data is processed instantly through PAFT iWMS with ERP synchronization.

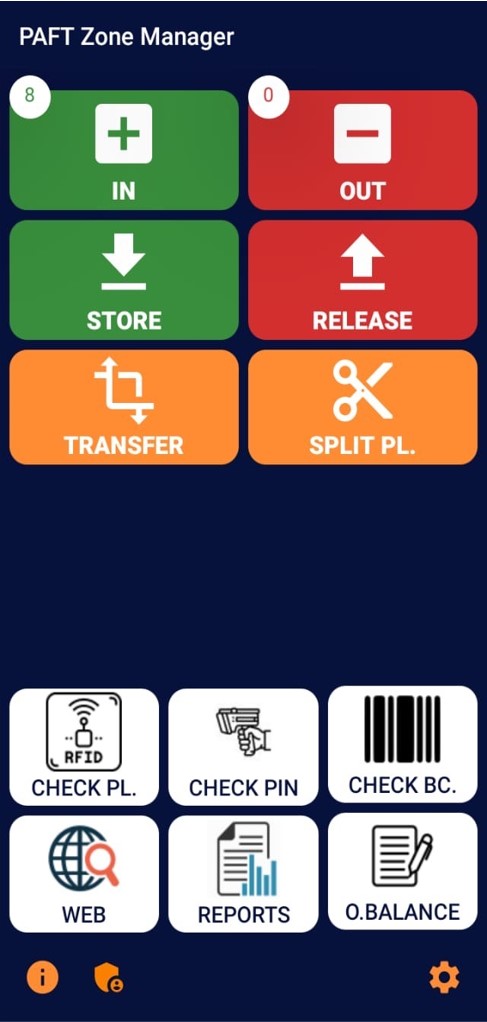

How PAFT iWMS Works

A seamless 5-step process from pallet to ERP

Smart Pallets

Each plastic pallet is RFID-enabled, providing full life traceability.

Smart Forklifts

Automatic reading of pallets during handling without manual scanning.

Smart Racks & Aisles

Instant location tracking and optimized storage management.

Smart Gates

Accurate inbound and outbound recording at warehouse gates.

ERP Integration

Real-time synchronization between iWMS and ERP systems.

Business Impact

PAFT iWMS enables real-time inventory tracking, improved accuracy, reduced labor costs, faster operations, and full warehouse visibility—positioning PAFT as a leader in smart pallet and warehouse automation solutions.

Radio Frequency Identification

Radio Frequency Identification (RFID) technology uses electromagnetic fields to automatically identify and track tags attached to objects. This technology significantly enhances the visibility and traceability of inventory items, making it an essential tool for modern warehouses.

Unlike traditional barcode systems that require line-of-sight scanning, RFID enables contactless reading of multiple items simultaneously. This capability dramatically speeds up inventory counts and reduces human error, allowing warehouse staff to focus on higher-value tasks while the system handles tracking automatically.

Implementation Success

While the PAFT iWMS offers numerous advantages, businesses must consider potential challenges such as initial setup costs and training requirements. Understanding these factors is crucial for a successful implementation and maximizing benefits.

However, the long-term ROI typically outweighs these initial investments. PAFT provides comprehensive onboarding support and training programs to ensure your team is fully equipped to leverage the system's capabilities from day one.

“PAFT provides comprehensive onboarding support to ensure your team is fully equipped from day one.”

Transform Your Operations

The PAFT iWMS with RFID technology revolutionizes inventory management. By embracing this innovative solution, businesses can achieve unprecedented levels of efficiency, accuracy, and operational excellence in their warehouse operations.

From real-time tracking to seamless ERP integration, PAFT provides a complete ecosystem that transforms how you manage inventory. Take the first step towards smarter warehouse management.